LOGO is a small Siemens PLC suited for implementing simple automation tasks in industry and building management systems.

It’s very user friendly and the last model is equipped with an Ethernet port for both programming and data exchange.

Communication

Due to its architecture, the LOGO communication is different from its Siemens cousins.

It implements two Ethernet

protocols, the first that we can call PG protocol, is used by the

software LOGO Comfort (the developing tool) to perform system tasks such as

program upload/download, run/stop and configuration.

The second, used for data exchange, is the well-known (from the Settimino point

of view) S7 Protocol.

They are very different, and the first is not covered by Snap7 and Settimino because is a stand-alone protocol that is not present, Is far I know, in different contexts.

To communicate with LOGO, the

Ethernet connections must be designed with LOGO Comfort in advance.

Of course I will show you how.

LOGO must be set as MASTER (i.e. NORMAL mode as LOGO Comfort says).

I assume that your LOGO Comfort is already set and connected to the LOGO.

Connection configuration

Configuring a server connection allows you to connect Settimino Client with LOGO for reading and writing the memory just like an HMI panel would do.

· In the Tools menu choose the Ethernet Connections item.

· Right click on ”Ethernet Connections” and click ”Add connections” to add a connection

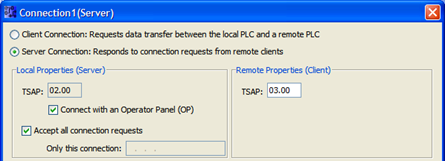

· Double-click the new connection created and edit its parameters selecting Server Connection.

Note:

1. “Connect with an operator panel” checkbox can be checked or unchecked.

2. If you uncheck “Accept all connections” you must specify the PC address (for now I suggest you to leave it checked).

You can chose for Remote TSAP the same value of the Local TSAP, in the example I used two different values to remark (as you will see) the crossing parameters.

· Confirm the dialog, close the connection editor and download the configuration into the LOGO.

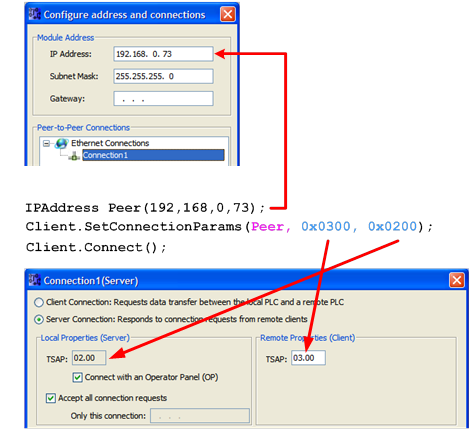

· The LOGO is ready, to test it run the ReadDemo, insert the LOGO IP Address and modify the connection routine as in figure.

Notice that the Local TSAP of the Client corresponds to the Remote TSAP of the LOGO and vice-versa. This is the key concept for the S7 connections.

The LOGO memory that we can

Read/Write is the V area that is seen by all HMI (and Snap7 too) as DB

1.

Into it are mapped all LOGO resources organized by bit, byte or word.

There are several tutorials in

the Siemens site that show how to connect an HMI (via WinCC flexible or TIA) to

the LOGO and the detailed map.

Please refer to them for further information.